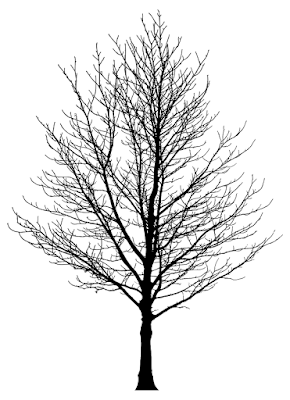

The first thing to do is to select a nice shape. I used a black and white SVG file for the tree that looked like this:

The SVG file is run though some program that generates the G-code, which is a list of commands that tells how the CNC machine shall move in order to cut the shape in the wooden board. I have made my own G-code generators, but there are both commerical and free tools available. I can recommand the free tool called F-engrave which is very a competent program.

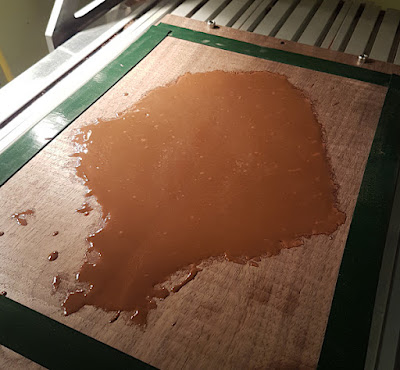

The CNC then gets to work and cuts the shape in the piece of wood.

It cuts the shape like a 'pocket' in the wood.

The pocket is filled with a mixture of two-component epoxy resin and pure copper powder of very fine degree.

Finally the excess resin is cut away, and the top surface is sanded and treated with oil or lacquer.